How To Make a Metal Cold Casting With Smooth‑Cast™ 325 Resin

Step 3: Back‑filling With Smooth‑Cast 325

Measure equal amounts of Smooth-Cast® 325 Part A and Part B by volume.

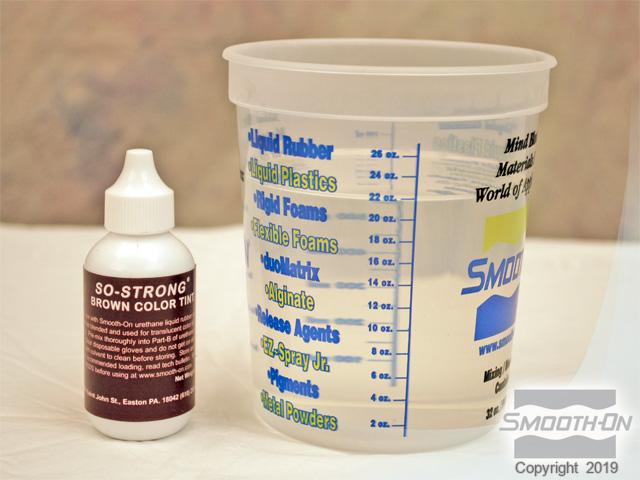

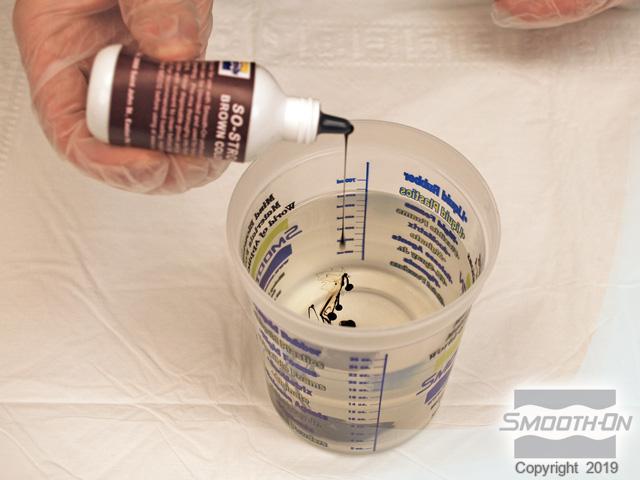

So-Strong® Brown tint will be used to match the base color of the bronze. Add a few drops of So-Strong® Brown tint to Part B and mix. The tint is thoroughly mixed into Part B prior to combining with Part A.

Smooth-Cast® 325 Part A is poured into a clean mixing container. The tinted Part B is combined with Part A. Mix the material thoroughly, scraping the sides and bottom of the container several times.

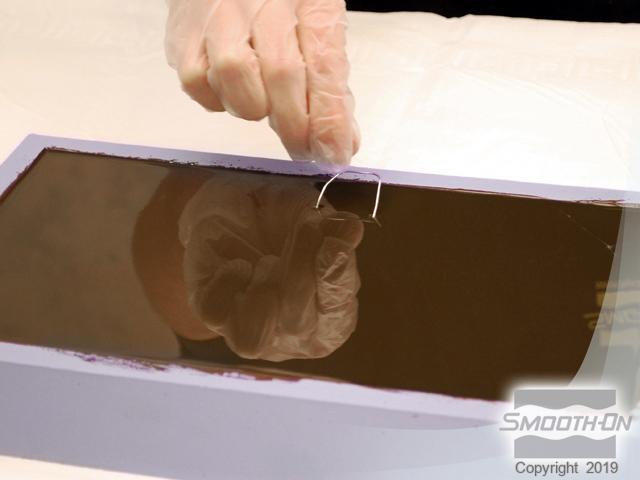

Pour the liquid into the center of the mold cavity until full. A bent paper clip or piece of wire can be carefully placed into the liquid resin to create a mounting hook. Once the resin cures, the piece will already be prepped to hang on a wall.

Allow the casting to cure for a minimum of 60 minutes before removing from the mold.