How To Make a Metal Cold Casting With Smooth‑Cast™ 325 Resin

Step 2: Mixing, Dispensing & Applying Smooth‑Cast 325

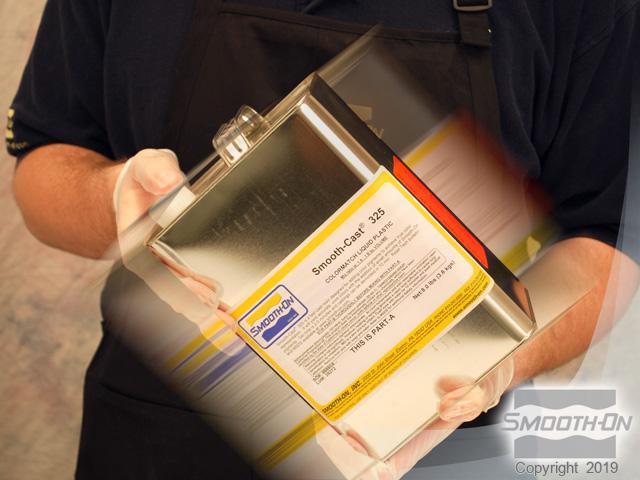

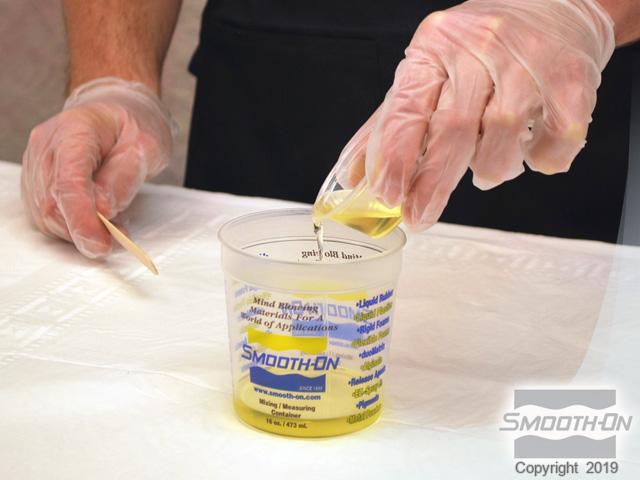

Stir or shake both Part A and Part B thoroughly before dispensing. Dispense the required amount of Smooth-Cast® 325 Part A into a measuring container. Then dispense an equal amount of Smooth-Cast® 325 Part B.

Smooth-On metal powders are -325 mesh and mix easily into Smooth-Cast® 325 resin. Dispense an equal volume of bronze powder. Equal amounts of Part A, Part B and bronze powder are ready to be combined.

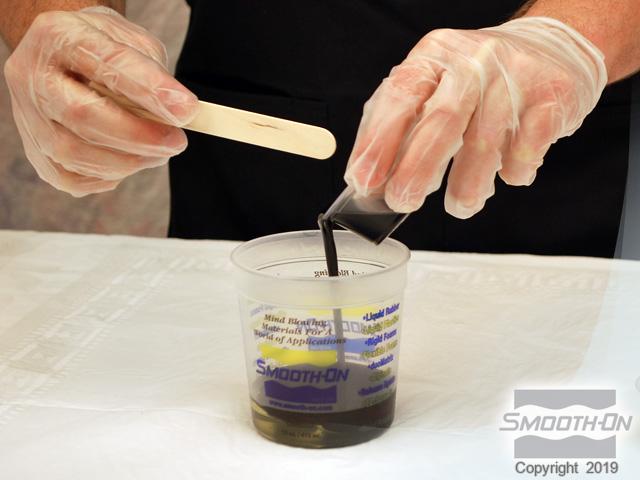

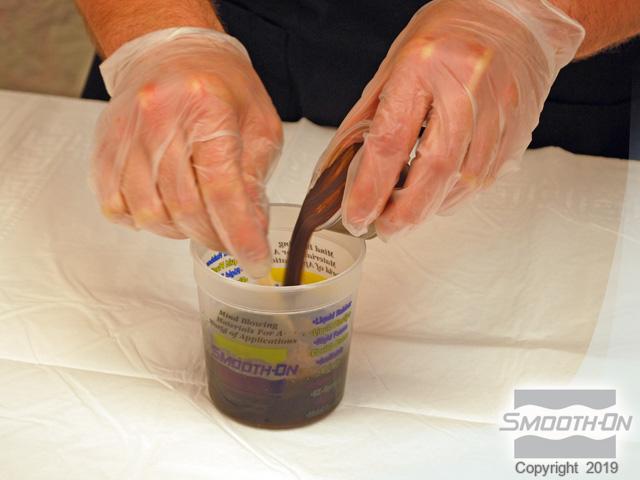

Two drops of So-Strong® Black tint are added to Smooth-Cast® 325 Part B. The tint is thoroughly mixed into Part B prior to combining with Part A. Part A is added to a clean mixing container. The tinted Part B is combined with Part A. Parts A and B are mixed thoroughly for 15 seconds.

Sift in Bronze Powder to the resin and mix all components for 30 seconds. Continually scrape the bottom and sides of the mixing container while stirring to keep the metal powder from settling on the bottom.

Pour the liquid into the mold cavity. Make sure you scrape any residual bronze powder from the cup. Immediately begin brushing the material around the mold cavity creating a ''gel coat.'' The mixture will continue to thicken as you brush. Once you feel the material starting to 'gel' or 'stick', stop brushing. Over brushing will result in a damaged casting.

After you stop brushing, allow the gel coat to partially cure for 5 - 10 minutes. Do not allow to fully cure, as delaminating may result between gel coat and back fill mixture.