How To Mold a Captain America Cosplay Helmet Using Rebound™ 25

Step 4: Preparing Model and Applying Free Form Air.

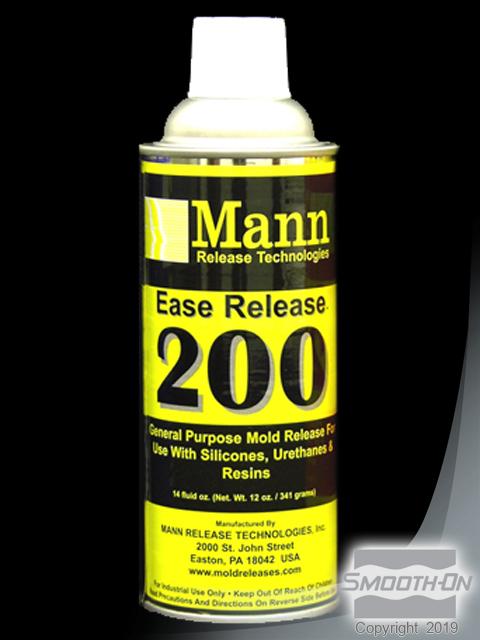

Before the rigid support shell is created, Ease Release 200 release agent, must be applied to the cured rubber or anywhere the shell will come into contact with it in order to prevent bonding. Use Free Form Air epoxy putty to create the 2-part rigid support shell. It has a mix ratio of 1A: 1B by volume. Dispense equal Parts of A and B and then mix and apply them to form the first half of the support shell. Make sure that the support walls are at least 3/8 inch in thickness. Allow to cure for 24 hours. Thoroughly apply Ease Release 200 on the cured Free Form Air support shell prior to applying the second half of the shell in order to prevent bonding. Allow to cure for 24 hours.