How To Make a Brush‑On Mold Using Dragon Skin™ Silicone Rubber

Step 9: Applying Third Part of Support Shell and Demolding Original

Brush Sonite® Wax over all surfaces. Spray an even coat of Universal Mold Release over all surfaces. Mix and apply Plasti-Paste® to section 3. Build Plasti-Paste® support shell to an ultimate thickness of 3/8'' (1 cm). Allow Plasti-Paste® to fully cure (approximately 90 minutes). Edges can be sharp and uneven so you can sand all edges smooth to make handling the mold easier.

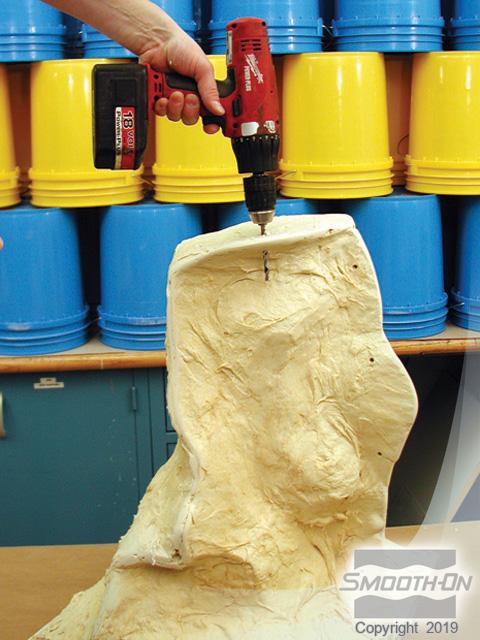

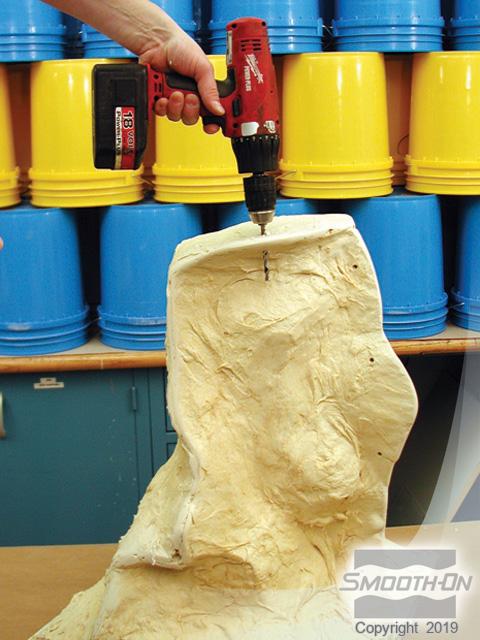

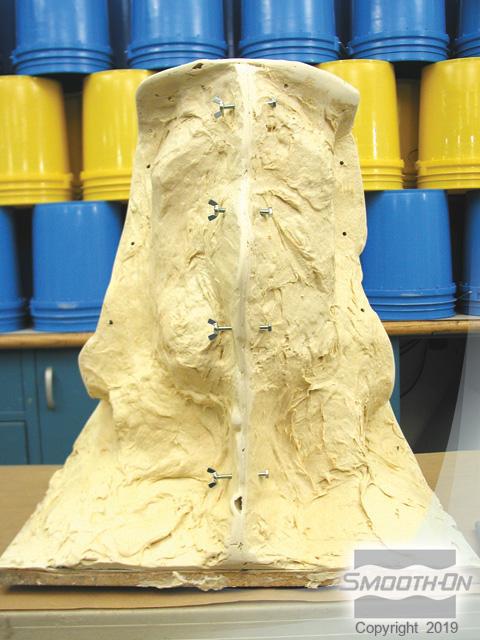

Bolts can be used to help lock the support shell sections together securely. Begin by drilling holes between sections. Bolts can also be placed though the top section of the support shell. Now the shell can be securely bolted together. Separate shell sections and remove the original model from the mold.

‹ Previous: Preparing and Building Part 2 of the support shell

Next: Preparing & Casting FlexFoam-iT X ›